It's critical to make comprehensive recovery of mineral and slags for sustainable development. New technology and equipment will be key factor.

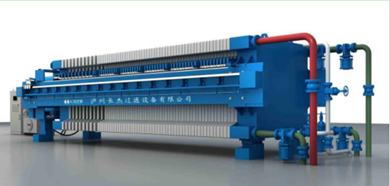

In order to cater to the marketing demands, we innovatively designed the CJW washing filter press. CJW can process the washing and filtration all-in-one. The comprehensive recovery of valued metals in the slags can be possibly maximumly reached. What’s more, it will reduce secondary pollution by harmful materials, perfectly process the washing and filtration for neutralization slag, acid leaching residues, and metal tailing slags. It’s the most effective and reliable solution for hydrometallurgy.

Let's introduce the CJW to you.

Benefits

※ The first CJW washing filter press was produced and successfully worked for lithium batteries industry in 2010.

※ The possible lowest moisture can reach to less than 8%.

※ The possible highest capacity can reach to 1500ton per day.

※ Save more investment and maintenance costs.

※ Washing efficiency can possibly reach to 99.5%, great help of comprehensive recovery.

※ Washing and filtration are processed all-in-one.

※ Zero reagents avoid secondary pollution.

※ Save at least 70% water.

※ Save at least 50% energy.

※ No need for huge gas tank

Successful stories for CJW in hydrometallurgy industry

Customer | Process | Application | Equipment | Results |

1 | Pressed with high temperature

Acid leaching

Filtration | Iron slags

90℃

Strong acid | washing filter presses | Iron slags moisture <30% Save 30% water compared to original equipment |

A technology company in Tianjin | Area: 400sq.m |

| ||

Qty: 3sets | ||||

Customer | Process | Application | Equipment | Results |

2 | Acid leaching with high temperature

Filtration | Acid leaching cobalt

80℃

Strong acid | washing filter press | Moisture <35% The original cobalt content is 1-2g/l, reduced to <10mg/l after washing by 2times water. |

A new material company in Hubei | Area: 160sq.m |

| ||

Qty: 1set | ||||

Customer | Process | Application | Equipment | Results |

3 | Testing line | Synthesis of Tungsten

50℃

Alkali | washing filter press | Moisture <25% Save at least 50% water compared to membrane filter press. |

A Tungsten company in Jiangxi | Area: 100sq.m |

| ||

Qty: 1set | ||||

Customer | Process | Application | Equipment | Results |

4 | Calcination lithium concentrates

Acid leaching

Filtration | Acid leaching lithium salt

Acid | washing filter press | Moisture <17% Less lithium chloride residues |

A Lithium company in Sichuan | Area: 140sq.m |

| ||

Qty: 2sets | ||||

Customer | Process | Application | Equipment | Results |

5 | Slag dust acid leading with high temperature

Filtration | Lead slag

90℃

Strong acid | washing filter press | Save over 20% water and energy compared to traditional process |

An environmental protection company in Jiangxi | Area: 220sq.m |

| ||

Qty: 1set | ||||

Customer | Process | Application | Equipment | Results |

6 | High Grade Nickel Matte pressed with high temperature

Acid leaching

Filtration | Removing iron

Precipitating Nickel

Squeezing and filtration

90℃

Strong acid | washing filter press | Ensured clean and clear filtrate. Recover at least 70% nickel by washing process. |

A new material company in Guizhou | Area: 200sq.m |

| ||

Qty: 3sets | ||||

Customer | Process | Application | Equipment | Results |

7 | Manganese sulphate with ammonia liquid

Produced by high temperature reaction tank | Mn₃O₄

60℃

pH=8-9 | washing filter press | Moisture <10% No ammonia smell after washing and drying |

A new material company in Guangxi | Area: 500sq.m |

| ||

Qty: 2sets |