Introduction:

A filter press is a specialized device used in various industries to separate solids from liquids efficiently. It consists of stacked filter plates with recessed chambers holding filter cloths. The slurry is introduced under pressure, allowing the liquid to pass through while retaining solids to form a filter cake.

Key Components and Operation:

Filter plates provide structural support and create individual chambers for the slurry. Our filter press utilizes patented filter plates, ensuring the production of uniform and homogeneous filter cakes. These innovative plates are designed to deliver consistent results and optimize filtration performance.

Filter cloths act as the primary filtration media, capturing solids while allowing the filtrate to flow through. Our patented filter cloth allows for efficient and environmentally-friendly cloth regeneration without the need for water. Moreover, the vulcanized rubber coating acts as a protective barrier, shielding the filter cloth from potential damage caused by abrasion or harsh chemicals. This not only extends the lifetime of the filter cloth but also reduces maintenance requirements and associated costs.

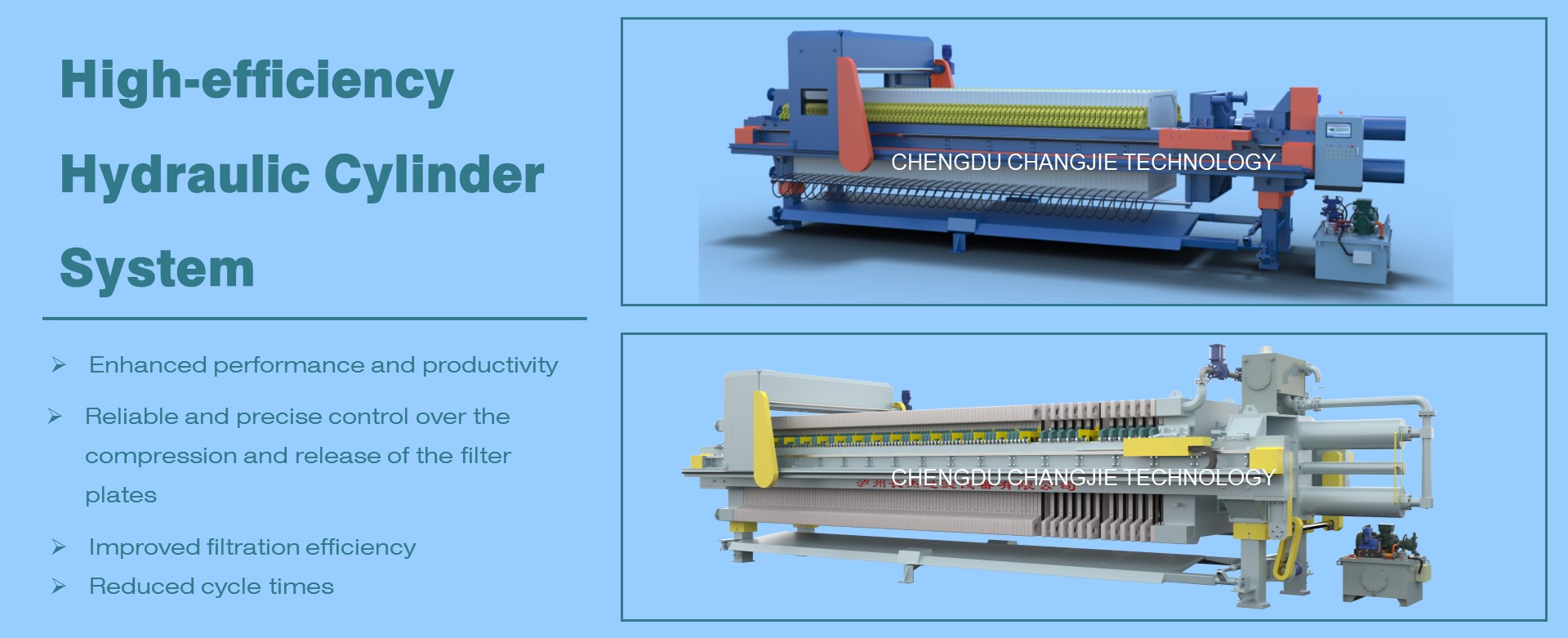

Hydraulic or mechanical force is applied to compress the plates and facilitate the separation process. Our filter press incorporates a high-efficiency hydraulic cylinder system. This hydraulic system is specifically designed to optimize the filtration process, providing enhanced performance and productivity. With its efficient operation, the hydraulic cylinder ensures reliable and precise control over the compression and release of the filter plates. This results in improved filtration efficiency, reduced cycle times, and increased overall productivity.

Benefits:

Efficient Solid-Liquid Separation: Filter presses offer high solids retention, producing clear filtrate and dry filter cakes for a wide range of slurry types.

Versatility: Customizable to different capacities, temperatures, and particle sizes, filter presses find applications in mining, chemical processing, wastewater treatment, and food processing.

Cost-Effectiveness: By minimizing waste disposal volumes and reducing the need for additional equipment or chemical treatments, filter presses optimize resource utilization and provide cost savings.

Environmental Sustainability: Filter presses contribute to environmental conservation through efficient wastewater treatment, sludge dewatering, and recycling processes.

Conclusion:

Filter presses are essential tools for effective solid-liquid separation in various industries. Our filter presses offer efficient filtration, versatility, cost-effectiveness, and environmental sustainability. We are continually optimized to deliver cleaner processes and a greener future.

With the contribution to resource efficiency, cost savings, and environmental protection, filter presses play a vital role in meeting industry demands. Our filter presses remain a trusted choice for solid-liquid separation needs across mining, mineral processing, metallurgy, coal, chemical processing, and other sectors.