The cake moisture is a criterial to judge the quality of product for concentrates. However, the moisture is high for hydrometallurgy. It will affect the comprehensive recovery and greatly increases the transportation and production costs. It’s proven that CJ series filter press can fix the problems and produce dry cakes which meet the requirements. In this case, we can help the customers to increase their profitability, save costs, energy and human power. Our CJ series filter presses have been working perfectly for many well-known mining companies in site.

Below is the brief introduction of our CJ filter presses.

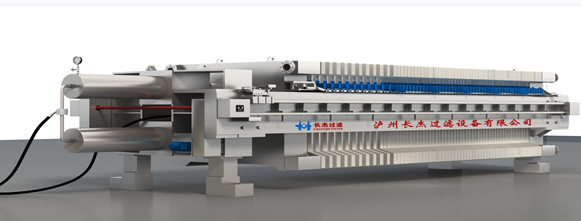

CJAH Automation High Efficiency Air-flow Filter Press

Technical characteristics:

※ Patented filter plate

※ Effective three-stage filtration for feeding, squeezing and drying.

※ Extremely low cake moisture, reaching to 5%.

※ High capacity up to 2500T per day.

※ High-speed hydraulic system and swinging for discharge ensure shorter cycling time.

※ Modularized design with high-automation and less wears ensure low operation and maintenance costs.

※ Hanging cloth with self-diagnosis.

※ Smart control system optional.

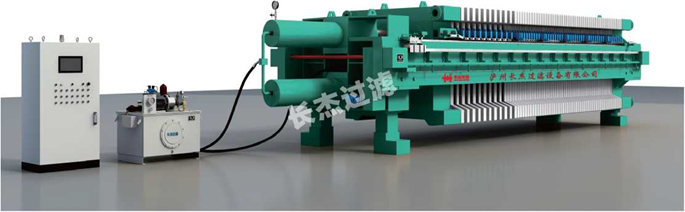

CJZH High Efficiency Automation Filter Press

Technical characteristics

※ Smart control system ensures stable quality.

※ High degree of automation with voice and video monitoring system.

※ Remote service

※ Three-stage effective filtration at feeding, squeezing and drying processes.

※ Extremely low cake moisture, reaching to 5%.

※ Patented cloth with self-diagnosis.

※ Modularized design for cost-effectiveness

Successful stories.

A copper plant of China Gold Group

Performance | Original equipment | CJ Filter Press | |

Ceramic Filter press | Tank Pressure Filter Press | ||

Moisture | >15% | 13% | <12% |

Remark | High moisture | High failure rate | Save costs |

A copper nickel plant in Gansu

Performance | Original equipment | CJ Filter Press | |

Ceramic Filter press | Vertical Filter Press | ||

Moisture | >15% | 9% | |

Remark | High moisture | High failure rate, maintenance costs up to 12Million per year | Capacity up to 800T per day. Greatly reduces maintenance costs. |

A gold plant in Hainan

Performance | Original process | CJ Filter Press |

all sliming cyanidation | ||

Moisture | ≤10% | |

Remark | NOT environmentally friendly. | Environmentally friendly |

A chemical company in Hubei

After much test and verifications, the customer selected CJ series filter press for filtration process of phosphate concentrates. The cake moisture is 10%.

A graphite company in Hunan

The customer selected CJ series filter press for filtration process of graphite concentrates and tailings. The cake moisture is 20%.

A environmental protection company in Shandong

Application: Antimony concentrates

Performance | Original process | CJ Filter Press |

Well-known membrane filter press | ||

Moisture | >20% | >15% |

Remark | Low capacity. Slurry leakage. Poor product quality for sales. | High capacity. Brilliant product quality. High efficiency. |

A copper plant of West Copper

Application: Lead, Zinc concentrates

Performance | Original process | CJ Filter Press |

Ceramic vacuum filter press | ||

Moisture | 10% | |

Remark | Cake moisture too high to be delivered for sales. | Low cake moisture. Save delivery costs and fix the problems for sales. |