The difficulties for filtration of Iron concentrates and tailings

The proven total reserves of iron ores in China are relatively abundant, but the reserves of high-grade iron ore are rare. The iron ores mainly belong to low-grade ores, possess 80% of the total proven reserves of iron ores. In addition, there are plenty of complex ores with multiple elements. It leads to the finer grinding of iron ores in multi-stages for reselection, the finer particle for iron concentrates and tailings. The CJ air-flow high efficiency can perfect meet the requirements for low cake moisture and high capacity.

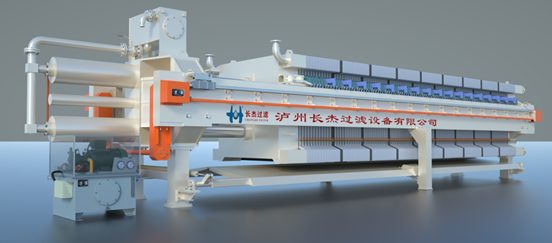

CJAH Automation High Efficiency Air-flow Filter Press

CJAH filter press has been successfully working for concentrates and tailings application in ferrous metals, non-ferrous metals, gold, nonmetal industries.

Technical characteristics:

※ Patented filter plate

※ Effective three-stage filtration for feeding, squeezing and drying.

※ Extremely low cake moisture, reaching to 5%.

※ High capacity up to 2500t per day.

※ High-speed hydraulic system and swinging for discharge ensure shorter cycling time.

※ Modularized design with high-automation and less wears ensure low operation and maintenance costs.

※ Hanging cloth with self-diagnosis.

※ Smart control system optional.

Some successful stories for filtration of iron concentrates / tailings

| A technology company in Tianjin | |

Application | Iron slags | |

Cake Moisture | 14-15% | |

Filtration Area | 410sq.m | |

Unit Capacity | 120t/d | |

Washing Efficiency | Save at least 50% energy and water. | |

The customer use CJW washing filter press for the hydrometallurgy project. The cake moisture is 4%-15%. Filtration rate is 24kg/㎡h. After washing by 1.5times water, the comprehensive recovery rate is very high. At least 50% energy and water consumption is saved compared to original process. | ||

| An iron plant in Vietnam | |

Application | Iron concentrates | |

Cake Moisture | ≤10% | |

Filtration Area | 580sq.m | |

Unit Capacity | 1000t/d | |

It's red iron ore which is difficult for filtration.The cake moisture is >15% for the test of membrane filter press. When the customer used CJ series filter press, the cake moisture is ≤10% and can be processed for smelting. The customer extremely reduced the maintenance costs. | ||

| A regenerated resources sales company in Sanmenxia | |

Application | Iron concentrates | |

Cake Moisture | ≤8% | |

Filtration Area | 512sq.m | |

Unit Capacity | 1200t/d | |

The customer mainly processes the smelting slags produced by smelters. The daily capacity is 1000ton. They originally used ceramic filter press for the filtration with a cake moisture around 16%. In addition, 40000 Chinese Yuan of Nitric acid would be required for washing monthly, leading to great costs waste and environmental pollution. After technical reform, the customer used 2sets of CJ air-flow high efficiency filter presses for the filtration of iron concentrates. The moisture for iron concentrates is <8% which met the requirements for production in site. | ||

| An environment protection company in Jiangxi | |

Application | Iron slags | |

Cake Moisture | <45% | |

Filtration Area | 210sq.m | |

Unit Capacity | 180t/d | |

Washing efficiency | >75% (the content of soluble zinc reduced from 18% to 4.5% with a moisture <45%) | |

The customer used CJ air-flow high efficiency filter press for the filtration of iron slags with perfect washing efficiency >75%. We help customer greatly shorten production process, save production costs and increase its capacity. | ||

| A copper company in Tibet | |

Application | Flotation Iron Concentrates | |

Cake Moisture | ≤10% | |

Filtration Area | 328sq.m | |

Unit Capacity | 600t/d | |

The customer used CJ air-flow high efficiency filter press to filtrate the iron concentrates by flotation. The cake moisture is less than 10% even at the high-altitude area and with ultra-fine particles. The unit capacity is over 600Ton per day. | ||

| A trading company in Sichuan | |

Application | Iron concentrates | |

Cake Moisture | ≤10.5% | |

Filtration Area | 512sq.m | |

Unit Capacity | 1000t/d | |

In order to raise the grade of the iron concentrates, the concentrates would be crushed and grinded finely to -400mesh 98%. The original ceramic filter press in site could not fit for finely application. After much work, communications, tests and verifications, the customer finally selected CJ air-flow high efficiency filter press for the filtration. The cake moisture was extremely low and greatly saved transportation costs. | ||