Filtration Equipment in Coal Preparation Plants: An Overview

In the realm of coal preparation, standard filtration methods encompass the utilization of regular chamber/membrane filter presses and tank-type pressure filter presses for processing flotation-cleaned coal. The moisture of the clean coal post-flotation typically ranges from 17% to 24%. While these methods are widely employed, certain challenges need to be acknowledged.

Beyond the elevated moisture levels in the filter cake, traditional chamber membrane filter presses are characterized by limited automation, modest production capacities, and labor-intensive manual cake discharge. Furthermore, operational concerns including significant leaks, suboptimal working conditions, and challenging on-site environments often arise.

Tank-type pressure filter presses exhibit intricate equipment configurations and, in some instances, operate at rates lower than 40% throughout the year. Alongside this, these press types exhibit high energy consumption, accounting for 18% to 30% of the total power consumption of the entire plant.

As the coal preparation industry seeks enhanced filtration solutions, addressing these challenges becomes crucial for achieving optimal efficiency and performance.

Revamping and Elevating Changjie Filter Press Solutions

Following the intense fervor of the "coal super frenzy" that dominated the market for two years, 2023 has ushered in a starkly contrasting phase in coal prices. A substantial downturn has been observed in the prices of domestic power coal, coking coal, and other coal varieties. Amidst these market dynamics, coal selection enterprises are confronted with a pressing challenge: how to economically revamp or upgrade their existing conventional chamber/membrane filter presses and tank-type filter presses.

Changjie Filter presents a comprehensive array of three distinct methods to rejuvenate traditional filtration equipment. Each method is accompanied by a detailed breakdown of its resultant effects, empowering you with the flexibility to make informed choices tailored to your specific needs.

For Chamber Filter Press Transformation

As part of our transformation approach for chamber filter presses, we propose a series of enhancements. This includes the replacement of existing chamber filter plates with either air-through chamber filter plates or air-through chamber membrane filter plates. In addition, we recommend a revamp of the piping system, the integration of supplementary air compressors and air storage tanks, and the optimization of the equipment's through-flow drying capabilities. By adopting these modifications, a substantial reduction of the moisture content in flotation clean coal, by a minimum of 5-10 percentage points, can be achieved. Moreover, these enhancements contribute to a decrease in auxiliary cake discharge actions, leading to a notable alleviation of labor intensity for operators.

For Chamber Membrane Filter Press Transformation

In the realm of chamber membrane filter press transformation, we present a comprehensive strategy for enhancement. This entails the substitution of the entire suite of through-flow filter plates, reconfiguring the piping system, integrating pneumatic squeezing and through-flow drying functionalities, introducing an air compressor, and expanding the capacity of the air storage tank for blowing operations. These strategic modifications collectively contribute to a remarkable reduction of a minimum of 5 percentage points in the moisture content of flotation clean coal. Notably, the sealing efficacy of the equipment experiences a significant boost, consequently streamlining the process of automatic and swift cake discharge.

Revolutionizing Tank-Type Pressure Filtration:

In the realm of tank-type pressure filtration optimization, we propose a direct replacement strategy that involves swapping out your existing equipment for the cutting-edge Changjie Intelligent Air-through High Efficiency Filter Press. This transformation yields a profound reduction in clean coal moisture, achieving impressive levels of 12-15%. Simultaneously, it engenders a remarkable elevation in calorific value, with enhancements spanning from 500 to 1100 kcal. A noteworthy benefit is the substantial 20% reduction in energy consumption, leading to operational costs of under 3 yuan per ton.

Technical Advantages of Changjie's Dedicated Coal Selection Air-through High Efficiency Filter Press:

In comparison to the limitations of traditional chamber membrane filter presses, characterized by elevated moisture, limited capacity, and the substantial energy consumption and high failure rate of tank-type pressure filter presses, the Changjie through-flow intelligent membrane filter press demonstrates remarkable attributes in the filtration of clean coal and tailings:

ü Achieves a moisture of 12-14% for flotation clean coal and 20-25% for raw coal slurry.

ü Ensures thorough cake saturation through efficient squeezing and complete drying.

ü Equipped with an intelligent control system to maintain consistent cake moisture levels and capacity.

ü Incorporates over 20 energy-saving optimizations, resulting in a minimum 40% reduction in electricity and gas consumption.

ü Utilizes a modular design with fewer vulnerable components, boasting high automation levels and minimal manual upkeep.

ü Features automatic monitoring of filter cloth integrity, slurry prevention, detection, and automated shutdown mechanisms.

Implements an external prevention and internal control mechanism to mitigate slurry leakage risks, facilitating unattended operation.

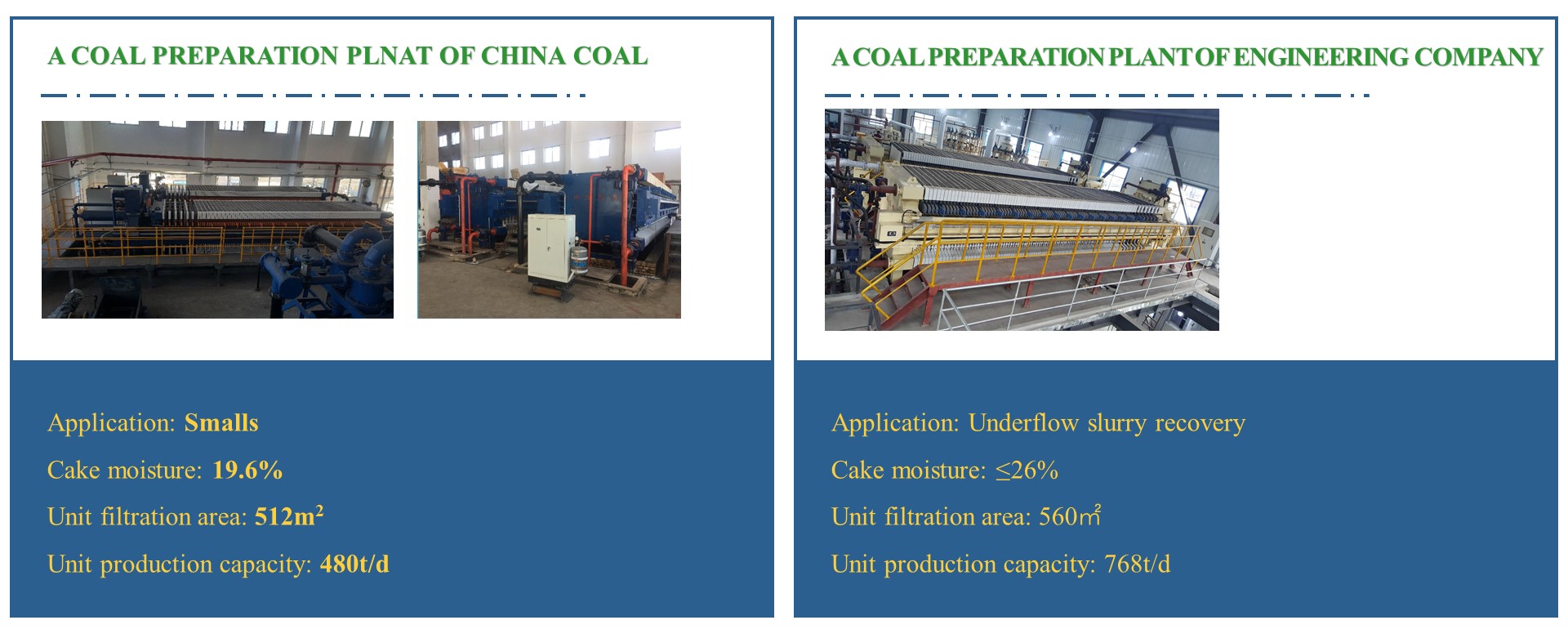

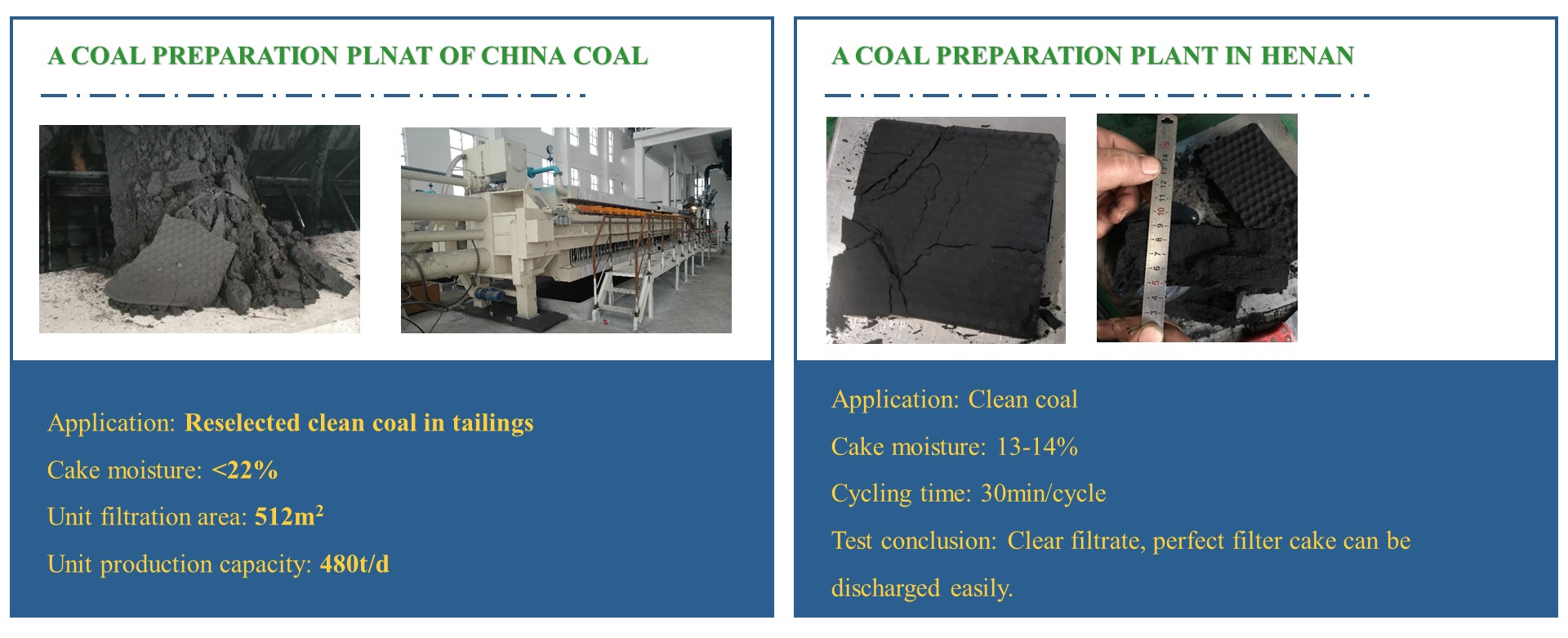

Classic Cases of Changjie Air-through High Efficiency Filter Press