Common Filtration Equipment in Coal Preparation Plants

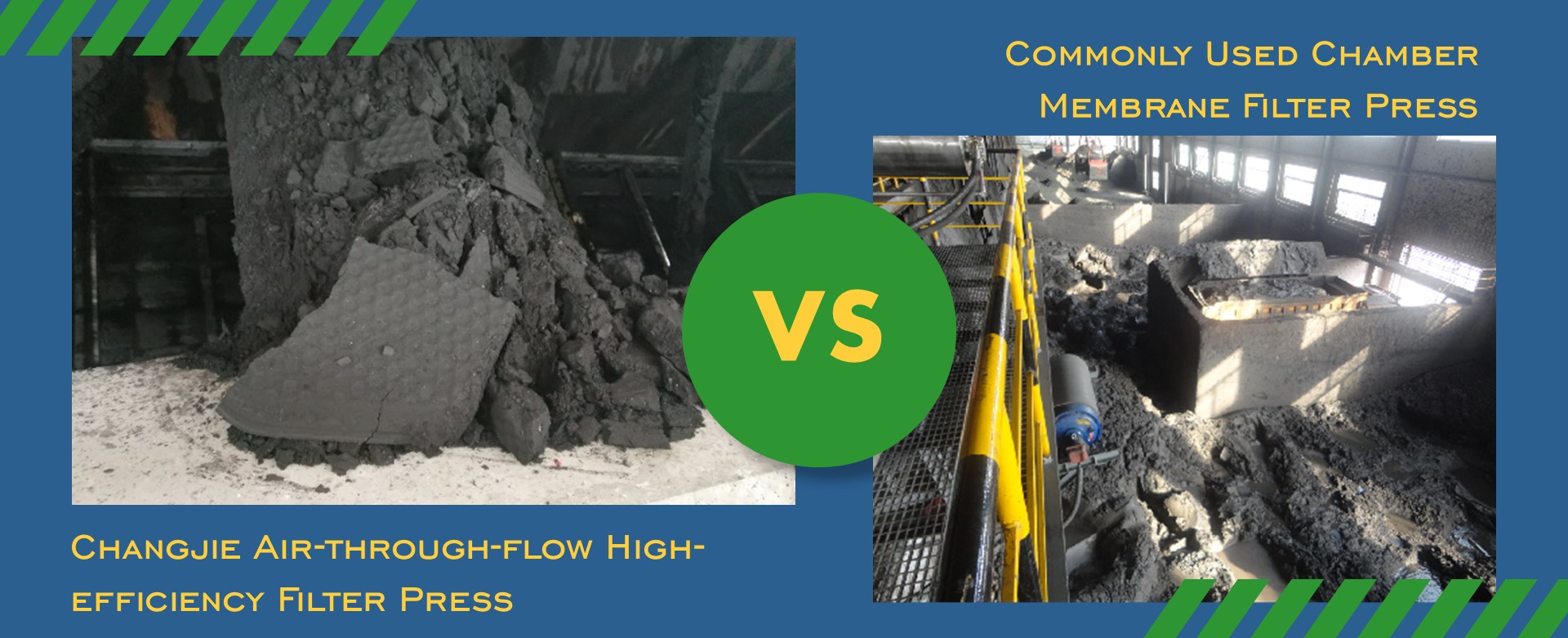

In the coal preparation industry, chamber/membrane filter presses and tank-type pressure filter presses are commonly used to filter flotation clean coal, with cake moisture rate typically ranging from 17% to 24%. However, these traditional filter presses often face challenges such as:

- high cake moisture rate

- low automation degree

- limited production capacity

- high labor intensity during discharge

- significant leaks during equipment operation

- and harsh on-site operating environments.

Tank-type pressure filter presses may also have:

- low utilization rates, some operating below 40% annually

- and exhibit high energy consumption, with electricity accounting for 18% to 30% of total power consumption in the plant.

Changjie Filter Press Transformation and Upgrading

After experiencing a booming coal market for two years, the coal prices in 2023 have shown a completely opposite trend. Domestic power coal, coke coal, and other coal prices experienced an overall decline. How to economically retrofit or upgrade the existing traditional chamber/membrane filter presses and tank-type pressure filter presses has become an urgent issue for coal preparation enterprises.

We provide you with three methods and corresponding results for the transformation of traditional filtration equipment for your selection:

For chamber filter presses: Replace the entire set with air-through-flow chamber filter plates or air-through-flow chamber membrane filter plates, modify the piping system, add air compressors and air storage tanks, and enhance the equipment's air blowing drying function. These can reduce the cake moisture rate of flotation clean coal by at least 5%-10%, significantly reduce the labor intensity of equipment-assisted discharge, and improve worker comfort.

For chamber membrane filter presses: Replace the entire set with air-through-flow filter plates, modify the piping system, add air pressure squeezing and air-through blowing drying functions, and configure air compressors with larger air storage tanks. This can reduce the cake moisture rate of flotation clean coal by at least 5%, greatly enhance equipment sealing performance, and achieve automatic and rapid discharge.

For tank-type pressure filters: We recommend direct replacement with brand new Changjie Air-through-flow High-efficiency Membrane Filter Press equipment, which can achieve clean coal with 12%-15% cake moisture rate, increase heating value by 500-1100 kcal, and reduce energy consumption by at least 20%, resulting in operating costs below 3 yuan per ton.

Technical Features of Changjie Air-through-flow High-Efficiency Filter Press for Coal Preparation

Compared to the high cake moisture of traditional chamber membrane filter presses and the high energy consumption and high failure rate of tank-type pressure filter presses, Changjie air-through-flow high-efficiency filter press exhibits significant advantages when filtering flotation clean coal:

- Achieves none-membrane filling squeezing on complete and consistent filter cake and effective airflow drying.

- Equipped with an intelligent operation control system, ensuring consistent and homogeneous cake moisture and capacity.

- Through more than 20 energy-saving optimizations, the equipment's electricity and gas consumption can be reduced by at least 40%.

- Modular design with fewer wear parts, high automation degree, and minimal manual maintenance required.

- Utilizes several patented technologies, including filter cloth regeneration, significantly extending spare parts' lifespan.

- Far superior to imitations in terms of enhanced sealing, drying design, energy efficiency, and reduced consumption.

- Clean coal filtration achieves cake moisture rate as low as 12-14%, and raw coal mud filtration reaches 20-25% cake moisture rate.

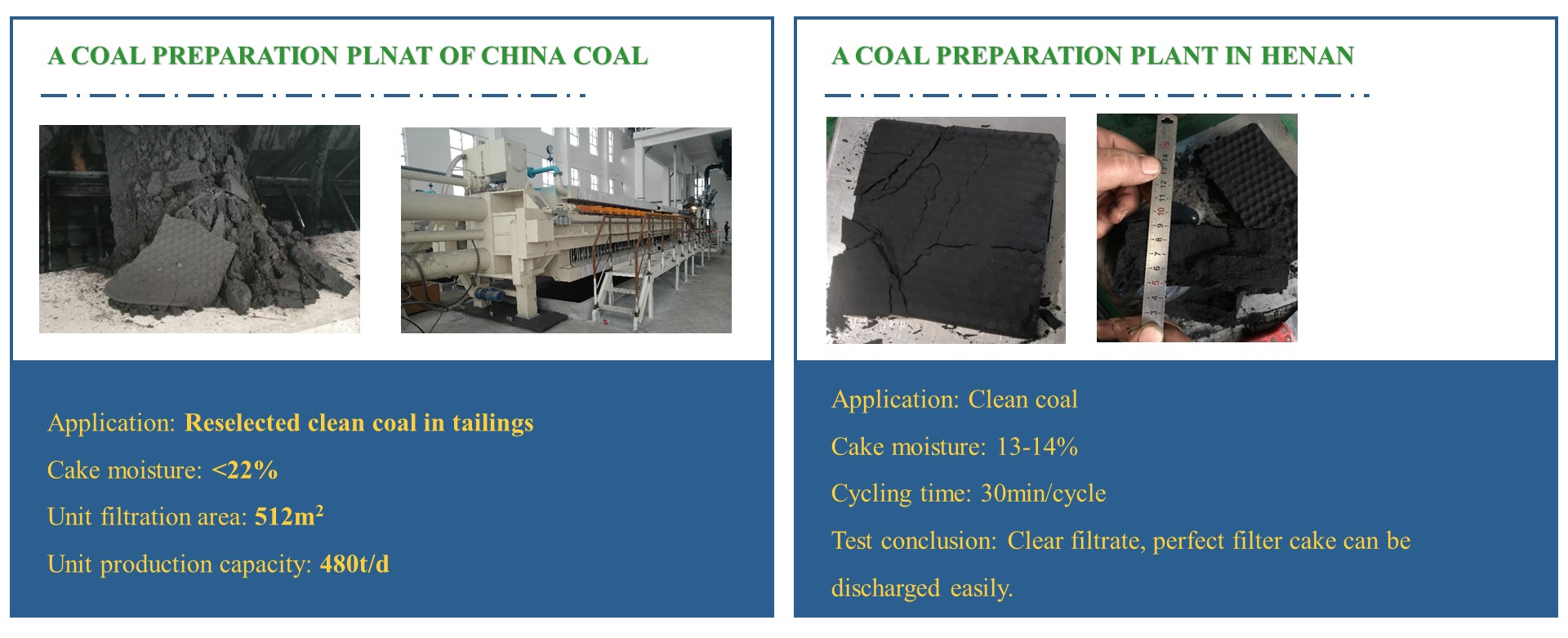

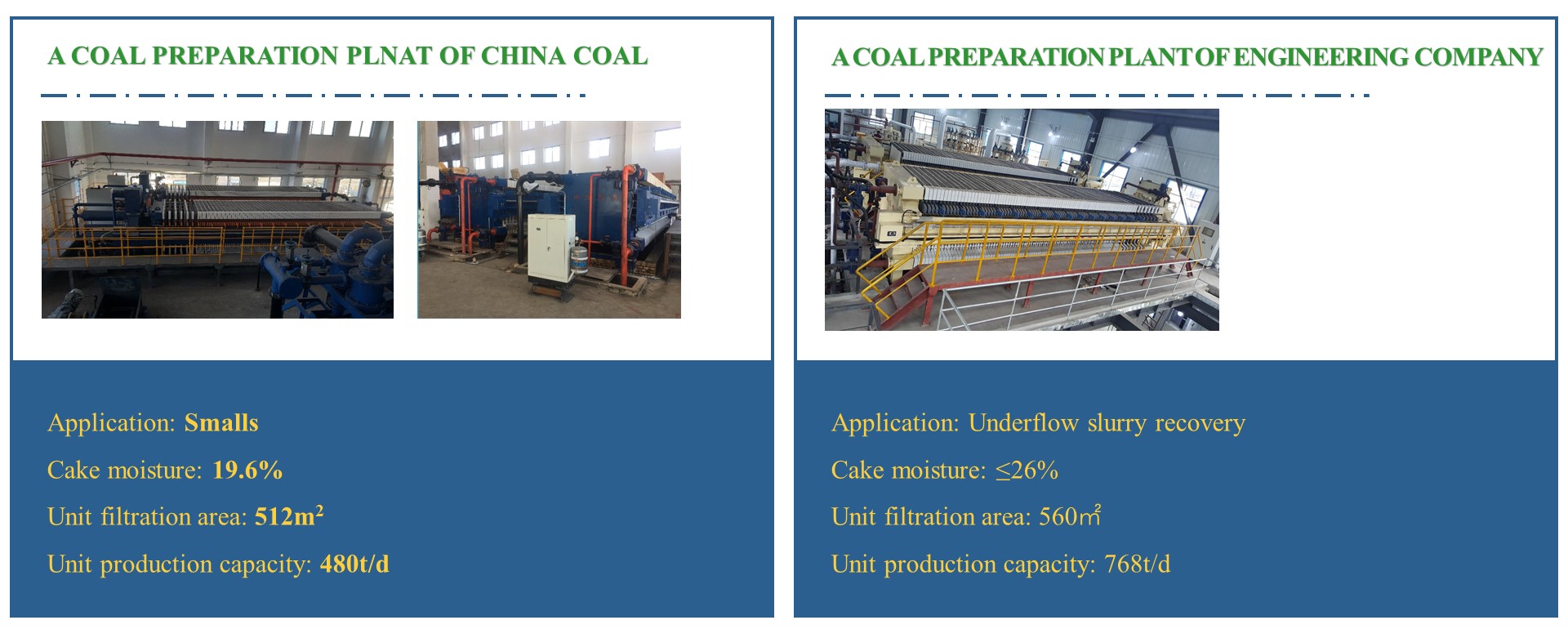

Classic Case of Changjie Air-through High-Efficiency Filter Press