Development demands in the coal washing industry

With the rapid advancement and delelopment of coal washing technology in our country, coal preparation plants are becoming larger in scale, separation efficiency is continuously improving, the quantity of fine-grained coal is increasing, and issues such as deteriorating coal quality and increasing coal slurry are also arising. To develop intelligent coal washing technology, improve the comprehensive utilization of coal, and achieve zero discharge of coal slurry, coal preparation plants have placed higher demands on the key equipment, the filter press in the dewatering process.

Commonly used coal washing filtration equipment

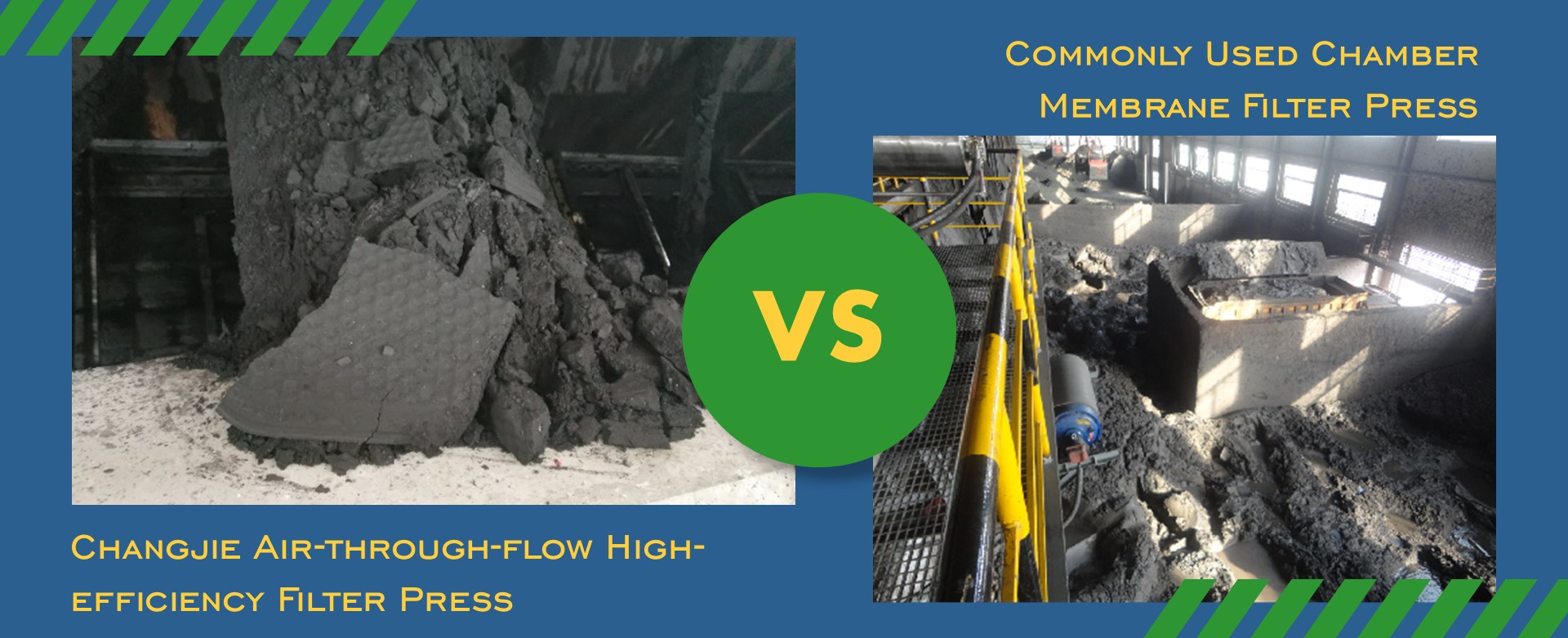

After 2005, the requirement for commercial coal demanded a moisture rate of less than 9%. However, the existing processes for dewatering flotation clean coal and tailings reprocessing generally rely on conventional chamber membrane filter presses or tank-type pressure filter presses, resulting in a moisture rate of around 17-24% after dewatering. The high moisture rate of the clean coal after pressing not only increases transportation and storage costs but also raises the direct utilization cost of subsequent coal. By adopting Changjie's specialized intelligent air-through-flow high-efficiency filter press for coal washing, compared to traditional filtration equipment, the moisture rate can be reduced by an average of 5-10 %, with a calorific value increase of 500-1100 kcal, and operating costs of less than 3 yuan per ton.

1. Chamber Membrane filter press:

Advantages: Simple structure and low cost.

Disadvantages:

Ø High moisture rate in the filter cake, making discharging difficult and requiring significant manual assistance.

Ø Low automation degree and limited production capacity.

Ø Prone to leakage, leading to unfavorable working conditions at the site.

Ø Short lifespan of filter cloth, resulting in high costs for spare parts and replacements.

2. Tank-type pressure filter press:

Advantages: High level of automation, allowing for continuous operation.

Disadvantages:

Ø Complex equipment structure, with an operating rate of less than 40%.

Ø High energy consumption, accounting for approximately 20% of the overall factory's electricity consumption.

Ø Rapid operation.

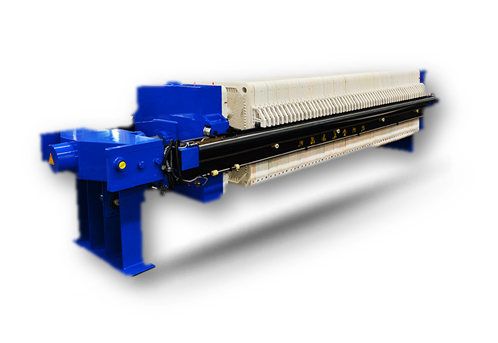

3. Changjie Intelligent Air-through High-Efficiency Filter Press

Ø Complete filtration and airflow feed-through pressing for the filter cake, with three-stage filtration process, resulting in the lowest moisture content of fine coal at 12-14%.

Ø Operating cost per ton is less than 3 yuan, leading to significant value-added benefits for the fine coal.

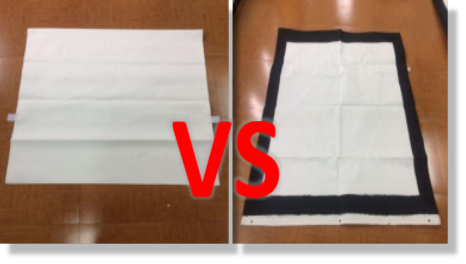

Ø Triple filter cloth regeneration technology extends the lifespan of filter cloth by at least 50%.

Ø Smart filter press system, enhancing the level of intelligent filtration and contributing to the development of smart coal washing plants.

Advancements in Changjie's Intelligent Air-through High-Efficiency Filter Press for Coal Washing

1. Three-stage complete and effective filtration process, resulting in a fine coal moisture content of 12-14%.

2. Triple filter cloth regeneration technology, significantly extending the lifespan of filter cloth by at least 50%.

3. Smart filter press system, contributing to the development of intelligent coal washing plants.

3.1 Achieving automatic interlocking control for feeding, ending feeding, and discharging in filter press units.

3.2 Equipped with a four-probe video monitoring and recording device with interfaces, facilitating centralized monitoring of coal washing plant equipment.

3.3 Implementing intelligent adjustments of feeding/pressing/drying pressures and time, with automated capacity recording.

3.4 Ensuring uniform and consistent filter cake moisture rate in every filtration cycle.

4. Multiple methods for automatic and rapid discharging.

4.1 Equipped with a multi-cylinder rapid pressing and opening technology for large-scale equipment, improving the overall operational efficiency.

4.2 Utilizes multi-plates vibrating discharging technology, significantly enhancing discharging efficiency and quality.

5. Low energy consumption, leading to at least 20% savings compared to imitations, resulting in lower operational costs.

In comparison to imitations with the same filtration area, Changjie's equipment saves at least 20% in power and capacity configuration for air compressors and air storage tanks, considerably reducing the owner's investment in drying and operational costs.

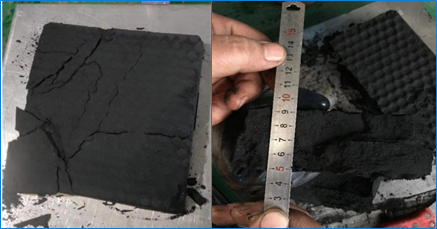

6. Patented filter cloth with enhanced sealing properties, preventing slurry spraying.

By employing the patented rubber vulcanization-formed filter cloth, the following advantages have been achieved:

6.1 Significantly enhanced equipment sealing properties.

6.2 Prolonged lifespan of the filter cloth.

6.3 Reduced compressed air consumption, resulting in lower operational costs.

6.4 Minimized capillary leakage, thereby lowering the risk of slurry spraying.

7. Continuous clarification technology ensures consistent filtration quality.

7.1 Advanced technology surpasses the simple turbidity judgment, enabling real-time diagnosis and filtration chamber shutdown in the event of independent filter cloth damage.

7.2 Substantially improves the clarity of the filtrate, preventing prolonged contamination and guaranteeing uniform filtrate quality.

8. Closed-flow equipment and rapid filter cloth damage diagnosis technology.

The use of patented filter plate with external U-shaped pipelines enables swift diagnosis of filter cloth damage in closed-flow equipment, reducing the labor intensity for workers.

9. Safety explosion-proof and arch-board burst prevention technology.

By implementing light curtain grid technology, an additional safety protection system is added for the deformation of filter press plates, preventing equipment damage and personnel injuries.

10. Slurry spraying cessation technology, slurry spraying warning, and one-click stop.

Through the use of photoelectric sensing and other technologies, the system can not only issue warnings for potential slurry spraying but also immediately halt any ongoing slurry spraying.

11. Safety monitoring technology.

Changjie's filter press electronic control cabinet is equipped with a 15-inch screen and a monitoring system with four probes, allowing operators to have a clear view of both sides of the filter press and the status of main auxiliary equipment, ensuring the safe operation of the equipment.

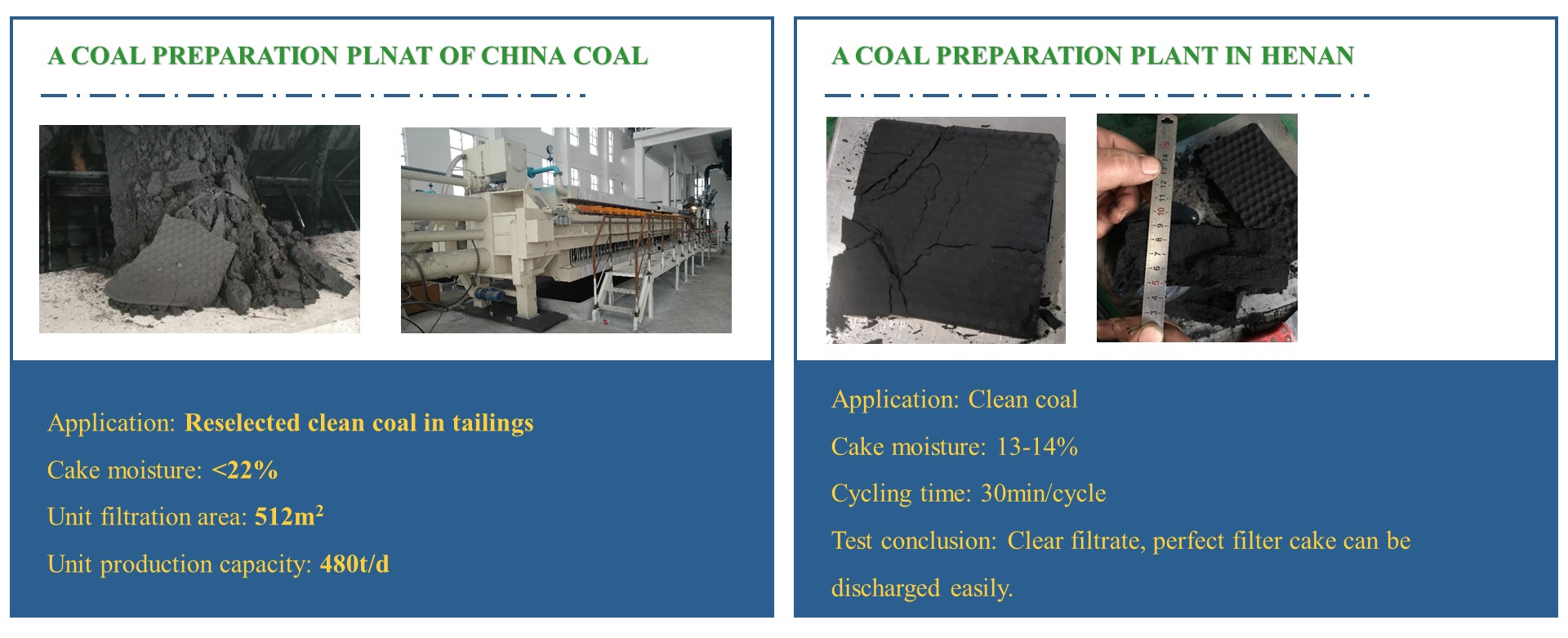

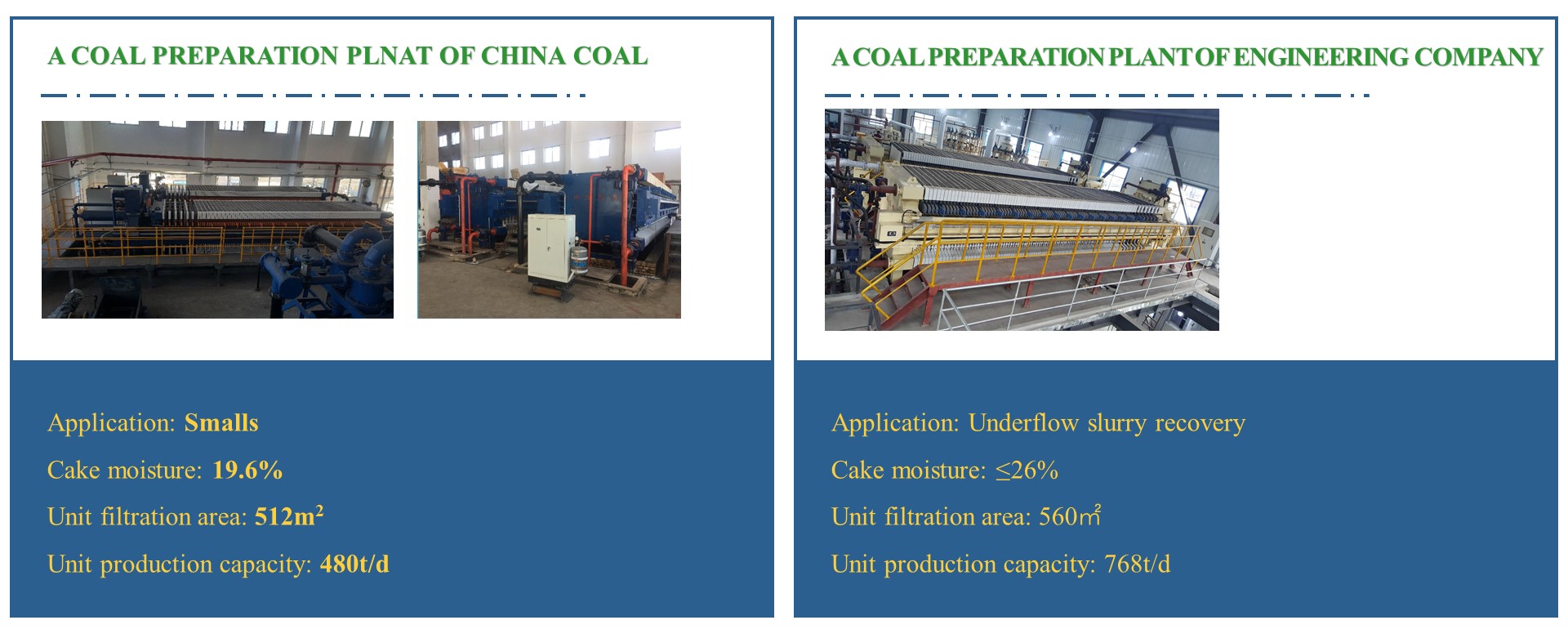

Partial Classic Case of CJ Filter Presses